Material guide — Laminate, linoleum & valchromat

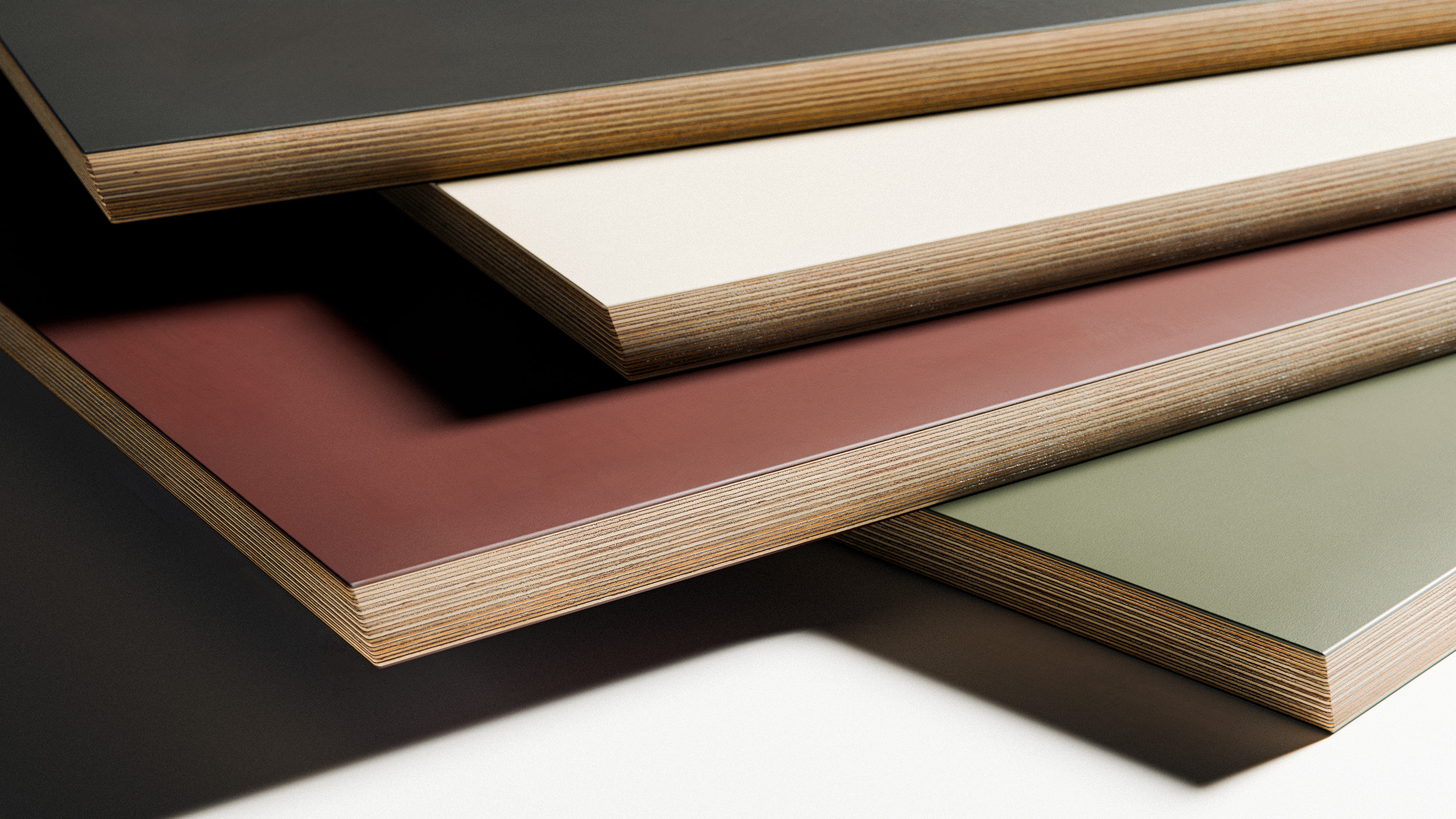

Laminate, nanolaminate, linoleum, and Valchromat are four modern materials frequently used for tabletops in both commercial and residential environments. They are particularly valued for their durability, practical properties, and, in several cases, their environmental benefits.

Choose the right material from the start

This guide provides an overview of each material type, focusing on advantages, limitations, and maintenance. By making an informed choice before purchasing, you reduce the risk of selecting a material that does not suit your needs. This will help you keep your furniture much longer – a smart choice for both the environment and your budget.

Laminate

Laminate is a highly appreciated material for surfaces exposed to daily wear. Its hard, dense surface makes it resistant to moisture, dirt, and impact, making it especially suitable for homes with children or environments where surfaces are used frequently.

High-Pressure Laminate (HPL)

High-pressure laminate is a reinforced version of standard laminate. It is manufactured by impregnating multiple layers of paper with resin and compressing them under high pressure and temperature. The result is an extremely compact and durable surface that can withstand heavy use. The difference between standard laminate and HPL is most noticeable in environments where heat or impact is common, but for everyday tabletops, regular laminate is often more than sufficient.

Advantages of laminate

Laminate is highly resistant to scratches and pressure. Its multi-layered structure creates a stable surface that withstands heavy use without significant wear. It is also one of the easiest materials to maintain. Thanks to its smooth, non-porous surface, dirt does not adhere easily, allowing laminate tabletops to be cleaned quickly and easily with water and mild detergent.

Laminate has low light sensitivity, particularly in white finishes, which retain their color even after prolonged sunlight exposure. Colored laminates may fade slightly over time, but compared to many natural materials, they offer excellent color stability.

In terms of water resistance, laminate performs very well. The surface withstands water and other liquids effectively. However, if the edges are made of wood or other absorbent materials, they may be affected if moisture penetrates the joints.

Limitations of laminate

Laminate has low sound absorption. In environments where acoustics are important, materials like linoleum may be a better option. Laminate is also sensitive to high heat directly on the surface. When used as a dining table, heat-resistant mats are always recommended to avoid damage.

Care instructions for laminate

For daily care, simply wipe the surface with a soft, damp cloth and mild dish soap. Always dry the surface afterwards to avoid water spots. For stubborn stains, use a cleaner designed for laminate, but avoid abrasive agents. Use only soft cloths, preferably microfiber, and avoid products containing acids, bleach, or solvents.

Nanolaminate (Fenix)

Nanolaminate is an advanced type of laminate that has become popular in modern interior design, especially for its aesthetics. It features an ultra-matte finish with low light reflection, giving it a soft and sophisticated look. The most well-known variety is Fenix, often used in designer tables.

The name refers to its technological production process. Nanolaminate is made using nanotechnology, where the surface is treated to be extremely dense, smooth, and non-porous. This makes the material not only visually appealing but also highly functional.

Advantages of nanolaminate

One of the most appreciated qualities is its resistance to fingerprints. Unlike many glossy surfaces, marks are rarely visible on nanolaminate, and if they do appear, they are easy to remove. It is also highly scratch-resistant and long-lasting. The surface is colorfast and does not significantly fade in sunlight.

A special advantage of Fenix is that minor scratches can be repaired using a process called thermal healing. This involves covering the scratch with a damp paper towel and gently applying heat with an iron to restore the surface.

Thanks to its dense structure, nanolaminate is also resistant to dirt and liquids. With no open pores for particles to enter, it is hygienic and easy to keep clean.

Limitations of nanolaminate

Despite its resilience, nanolaminate is sensitive to heat. Hot dishes or pans should never be placed directly on the surface. It also has no sound-absorbing properties, which can affect acoustics in some spaces.

Care instructions for nanolaminate

Clean with a soft cloth and mild cleaner. Avoid abrasives, acids, and harsh chemicals. Thermal healing can be used for superficial scratches on Fenix surfaces, but should always be done according to the manufacturer’s instructions. Ensure the iron never comes into direct contact with the surface to prevent damage.

Linoleum

Linoleum is a classic, natural material that has experienced a revival in contemporary furniture design. It is often used as a tabletop surface, especially in combination with wood, creating both visual contrast and functional benefits. Its soft yet durable surface makes linoleum a sustainable choice, available in a wide range of colors.

Advantages of linoleum

Linoleum is made from renewable materials, where linseed oil and resin are combined with fillers such as cork powder or wood fiber. This results in an eco-friendly material with low environmental impact. The surface is pleasant to touch, has a low reflection rate, and ages gracefully. Minor scratches tend to blend in over time, particularly with proper care.

It is also colorfast in sunlight. Unlike wood, its tone does not noticeably change even with long-term exposure. Linoleum naturally absorbs sound, making it ideal for large or open spaces where sound tends to bounce.

Limitations of linoleum

Linoleum is more sensitive to liquids than laminate. Spills should always be wiped up immediately, especially colored liquids like coffee or wine, as the surface can stain. It is also not suitable for use with sharp objects, so cutting directly on the surface should be avoided. Linoleum is sensitive to heat, meaning candles and hot pots must be placed on protective mats.

Care instructions for linoleum

For everyday cleaning, wipe the surface with a damp cloth. Always dry it afterwards to prevent water marks. To preserve its natural qualities and protect it from wear, the surface should be treated regularly with linoleum soap. This nourishes the material and creates a protective layer without making it sticky. If the surface feels oily, it may indicate over-treatment, which can be corrected with a linoleum-specific cleaner.

Valchromat

Valchromat is a through-coloured wood fibre panel that combines the visual appeal of wood with the technical benefits of modern board materials. It resembles MDF in some ways, but is around 40% harder, fire-rated to the same level as gypsum board, and offers significant improvements in strength, machinability, and design flexibility.

The material is produced by individually dyeing the wood fibres with non-toxic pigments and binding them together with natural resin. This composition is certified for use in products such as toys and children’s furniture. The result is a panel that is coloured all the way through, meaning the colour remains intact even when machined or scratched. This makes Valchromat particularly well-suited for CNC routing and furniture design where edges and details are visible.

Advantages of Valchromat

Because the material is coloured throughout, there are no visible marks from surface scratches or machining. Valchromat is more dimensionally stable than standard MDF and is less affected by moisture and temperature changes, making it a reliable choice in varied environments.

It is easy to work with – the board can be sawn, milled, and drilled without splintering, which is highly valued by designers working with precision. The surface has a warm and natural character thanks to the visible wood fibres despite the colouring. In many cases, FSC-certified wood is used in production, making Valchromat a more sustainable alternative to many other fibreboards.

Limitations of Valchromat

Valchromat requires a surface treatment to withstand everyday use. Without protection, it is sensitive to dirt, liquids, and UV light. Recommended treatments include lacquer or raw linseed oil – hard wax can be used, but has in some cases led to issues such as uneven finish.

Before treatment, the surface is relatively soft and may be damaged during use. Valchromat is also available in a more limited range of colours compared to laminate, which can make matching specific colour palettes more challenging.

Care instructions for Valchromat

Treated Valchromat is easy to clean. A damp cloth and mild cleaner are usually sufficient. If treated with oil or wax, the surface should be re-treated regularly to maintain protection. Avoid strong chemicals and abrasive cleaners, as they may damage the surface and color.

When re-treating, it is best to use the same type of finish as originally applied. This helps maintain a consistent, long-lasting surface that resists wear while preserving Valchromat’s natural character.

Laminate vs Linoleum vs Valchromat

Choosing a tabletop material is not always straightforward. To make comparison easier, we have assembled a side-by-side overview where laminate, linoleum and Valchromat are evaluated across key properties.

The colored circles indicate performance in each category. Green means best in that specific comparison, yellow means even or mid-level, and red means the material is not the strongest choice in that aspect. It does not mean the material is poor overall — it simply excels in other areas. Use this to match the right surface to your needs and environment.